Understanding the Fundamentals and Applications of Plastic Extrusion in Modern Manufacturing

In the realm of modern-day production, the method of plastic extrusion plays a crucial function - plastic extrusion. This complex procedure, including the melting and shaping of plastic through specialized dies, is leveraged across numerous markets for the development of diverse items. From car parts to durable goods packaging, the applications are vast, and the potential for sustainability is just as remarkable. Untangling the basics of this process discloses real adaptability and potential of plastic extrusion.

The Basics of Plastic Extrusion Process

While it might appear facility, the principles of the plastic extrusion procedure are based on reasonably simple principles. It is a manufacturing procedure in which plastic is melted and after that formed into a constant account via a die. The raw plastic product, commonly in the form of pellets, is fed right into an extruder. Inside the extruder, the plastic goes through heat and stress, triggering it to melt. The liquified plastic is after that compelled with a designed opening, understood as a die, to form a long, continuous product. The extruded product is cooled and after that cut to the desired size. The plastic extrusion procedure is extensively used in various sectors because of its flexibility, cost-effectiveness, and effectiveness.

Different Kinds of Plastic Extrusion Methods

Structure upon the fundamental understanding of the plastic extrusion process, it is required to discover the various methods entailed in this production approach. Both main methods are profile extrusion and sheet extrusion. In profile extrusion, plastic is thawed and formed right into a continual profile, often utilized to create pipelines, rods, rails, and window frames. In comparison, sheet extrusion creates big, level sheets of plastic, which are typically more processed into items such as food product packaging, shower curtains, and automobile components. Each method needs specialized machinery and precise control over temperature and stress to make certain the plastic keeps its shape throughout air conditioning. Recognizing these techniques is key to utilizing plastic extrusion properly in modern manufacturing.

The Role of Plastic Extrusion in the Automotive Market

A frustrating bulk of components in modern vehicles are products of the plastic extrusion process. Plastic extrusion is mainly utilized in the manufacturing of different vehicle elements such as bumpers, grills, door panels, and control panel trim. Hence, plastic extrusion plays a pivotal duty in vehicle manufacturing.

Applications of Plastic Extrusion in Consumer Item Manufacturing

Past its substantial influence on the automotive market, plastic extrusion proves just as reliable in the realm of durable goods producing. This procedure is critical in creating a large selection of products, from food product packaging to house appliances, playthings, and also medical gadgets. The adaptability of plastic extrusion enables producers to make and create complex sizes and shapes with high precision and effectiveness. In addition, due to the recyclability of several plastics, extruded elements can be recycled, reducing waste and price. The adaptability, flexibility, and cost-effectiveness of plastic extrusion make it a favored option for several consumer goods producers, contributing substantially to the sector's development and technology. The environmental effects of this widespread usage call for careful factor to consider, a topic to be talked about further in the subsequent section.

Ecological Effect and Sustainability in Plastic Extrusion

The prevalent usage of plastic discover this extrusion in manufacturing invites examination of its eco-friendly effects. Efficient equipment decreases power use, while waste management systems reuse scrap plastic, reducing raw product demands. Regardless of these renovations, further technology is required to reduce the ecological footprint of plastic extrusion.

Verdict

In final thought, plastic extrusion plays a crucial duty in modern manufacturing, particularly in the automotive and durable goods markets. Its adaptability enables the manufacturing of a vast array of elements with high accuracy. Its potential for recycling and advancement of biodegradable products offers an encouraging avenue towards sustainable practices, thus dealing with Home Page ecological issues. Recognizing the basics of this procedure is key to enhancing its benefits and applications.

The plastic extrusion process is thoroughly made use of in numerous sectors due to its cost-effectiveness, effectiveness, and flexibility.

Structure upon the standard understanding of the plastic extrusion procedure, it is essential to check out see post the various techniques involved in this manufacturing approach. plastic extrusion. In contrast, sheet extrusion creates huge, level sheets of plastic, which are generally further refined into items such as food packaging, shower drapes, and auto components.A frustrating majority of components in contemporary cars are items of the plastic extrusion process

Danny Tamberelli Then & Now!

Danny Tamberelli Then & Now! Haley Joel Osment Then & Now!

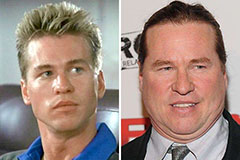

Haley Joel Osment Then & Now! Val Kilmer Then & Now!

Val Kilmer Then & Now! Jenna Von Oy Then & Now!

Jenna Von Oy Then & Now! Mike Smith Then & Now!

Mike Smith Then & Now!